In the realm of modern technology, the choice of materials is paramount, particularly in sectors that demand extreme durability and resilience, such as nuclear energy and military applications. These environments often subject materials to unrelenting forces, including high pressure, temperature extremes, and corrosive substances. Consequently, it becomes crucial to delve into the lattice-level behavior of materials to pave the way for the development of next-generation substances that are not only more robust but also economically viable and environmentally sustainable.

Recent groundbreaking research led by scientists at the Lawrence Livermore National Laboratory (LLNL) has provided fresh insights into the behaviors of single-crystal zirconium when subjected to high pressures. This research, detailed in the esteemed journals Physical Review Letters and Physical Review B, has revealed that zirconium deforms in unexpectedly intricate patterns under stress. Findings demonstrate that materials under extreme conditions utilize various mechanisms, such as dislocation slip, crystallographic twinning, and shear-induced amorphization, to alleviate shear stresses.

The lead author of the study, LLNL scientist Saransh Soderlind, emphasized the importance of understanding these microscopic processes for the creation of predictive models regarding material performance. Zr is unique as its plastic deformation characteristics are modified by pressure-induced changes in its crystal structure, resulting in a more complex behavior compared to other metals.

A key element of this exploration was the team’s use of femtosecond in-situ X-ray diffraction, enabling them to observe the atomic behavior of compressed single-crystal zirconium within nanosecond timeframes. This high-resolution imaging uncovered atomic disorder—an otherwise unseen phenomenon in elemental metals—and pointed to multiple pathways for crystallographic transformations. Such findings were stellar, as similar phenomena had remained undetected in polycrystalline zirconium.

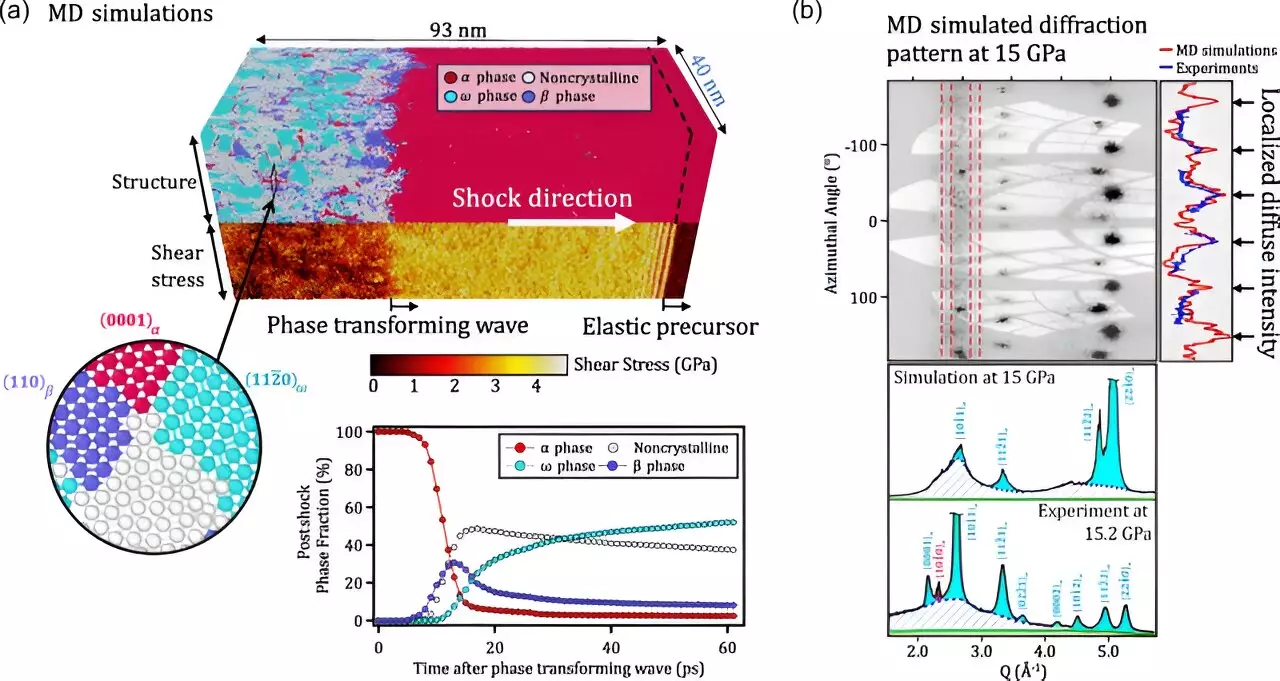

The researchers complemented their experimental techniques with multi-million atom molecular dynamics simulations, further validating their observations. They utilized machine-learned potentials to gain deeper insights into the deformation processes. This combination of experimental and computational approaches is providing unprecedented clarity into the way metals respond to extreme conditions.

The results uncovered by this study illuminate a more detailed understanding of metal deformation under extreme conditions than what was previously comprehended. As LLNL scientist Raymond Smith noted, this complex web of atomic activity is likely not unique to zirconium and could be of equal significance in other materials exposed to high pressures.

Given that zirconium alloys are extensively utilized in the nuclear industry—primarily in fuel rod cladding due to their exceptional strength and minimal neutron absorption—the implications of this research could be profound. The findings could not only enhance material performance in nuclear applications but also foster advancements in other sectors where high resilience to harsh conditions is critical.

Overall, this research represents a crucial step forward in understanding material behavior, promising deeper insights that could fundamentally transform the development of resilient materials for extreme environments.