In recent times, the quest for alternative energy storage solutions has taken a pivotal shift towards sodium-ion batteries (SIBs). These batteries present a promising alternative to lithium-ion batteries due to the abundance and accessibility of sodium, which is derived from common salt. Sodium’s environmental beneficence is augmented by its lower reactivity compared to lithium, offering a safe, efficient energy storage solution that holds potential for applications requiring quick charging and stable performance in lower temperatures. Nonetheless, sodium-ion batteries have not yet achieved widespread success, primarily due to inherent challenges related to their energy density and lifespan.

One of the most significant hurdles faced by sodium-ion technology is the need for specialized anodes. Sodium ions, being larger than their lithium counterparts, necessitate the use of hard carbon, a non-natural material that must be synthesized. The conventional method for creating hard carbon involves intricate carbonization of hydrocarbon sources, which entails heating this organic matter in an oxygen-free environment at temperatures surpassing 1,000°C for an extended duration. This process is both economically and environmentally taxing, creating a barrier to the commercialization of sodium-ion batteries.

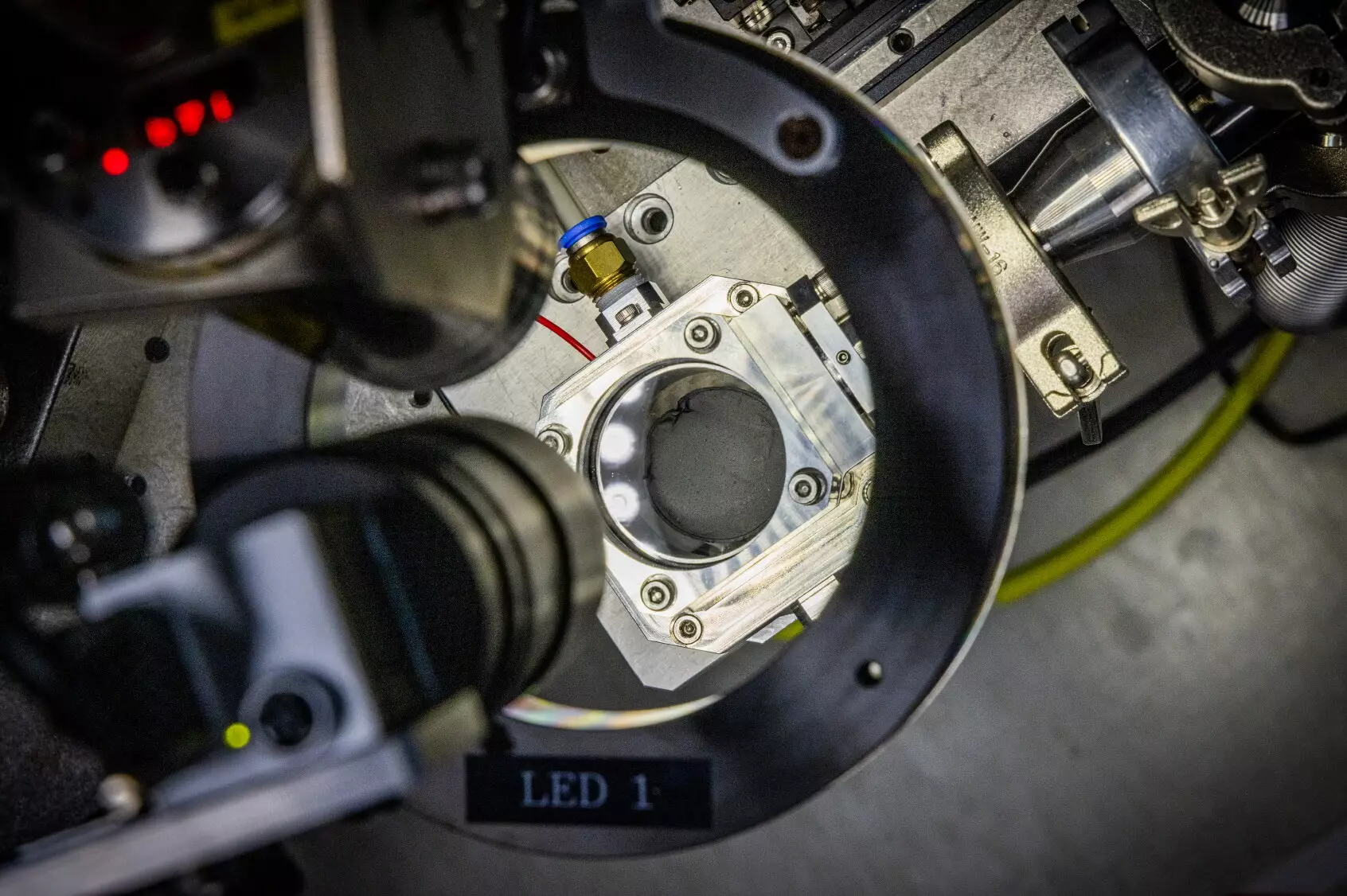

A transformative approach has emerged from a research team led by Dr. Daeho Kim and Dr. Jong Hwan Park at the Korea Electrotechnology Research Institute (KERI). They have harnessed microwave induction heating technology, akin to that utilized in everyday microwave ovens, to expedite the synthesis of hard carbon anodes significantly. By creating films that combine polymers with highly conductive carbon nanotubes, the researchers aptly applied microwave magnetic fields to induce localized heating, achieving temperatures greater than 1,400°C in a mere 30 seconds.

This leap in processing time not only reduces energy consumption but also enhances the viability of sodium-ion batteries in commercial applications. The rapid heating method employed by this innovative team circumvents the limitations of traditional carbonization methods, addressing both efficiency and environmental concerns.

The team’s successes are rooted in their robust understanding of the electromagnetic and thermal behaviors of nanomaterials when exposed to microwave fields. They employed a novel “multiphysics simulation” technique, which allowed for an exploration of the intricate processes at play. This nuanced comprehension enabled the formulation of a new and efficient way to prepare sodium-ion battery anodes, a breakthrough promising to elevate SIB technology to new heights.

Their findings, detailed in the Chemical Engineering Journal, hold implications for future battery design and manufacturing processes. Notably, student researchers Geongbeom Ryoo and Jiwon Shin played a role in these advancements, emphasizing the importance of collaborative efforts in academic research.

Looking ahead, the KERI team plans to refine their hard carbon anodes’ performance while developing methodologies for large-scale, continuous production of these materials. They acknowledge the potential of applying their microwave induction technology across other fields, such as in the production of solid-state batteries that demand high-temperature sintering processes.

As public interest in safer battery technologies grows—especially after incidents involving electric vehicle fires—the implications of this research are significant. Dr. Jong Hwan Park stresses that the advancements in sodium-ion battery technology could lead to a safer and more efficient means of energy storage.

Furthermore, KERI has already filed a domestic patent for this groundbreaking technology, raising anticipation for prospective partnerships with industry players focused on energy storage solutions.

The pioneering work of Dr. Kim and Dr. Park signifies a critical step toward overcoming the barriers that have long plagued sodium-ion technology. By utilizing advanced microwave heating techniques to streamline the production of hard carbon anodes, they provide a glimpse into a future where sodium-ion batteries could supplement or even surpass lithium-ion systems in various applications.

The implications of their research extend beyond academic borders, potentially laying foundational work for safer, more efficient energy storage solutions in an increasingly energy-conscious world. As interest in sustainable technologies continues to rise, the advancements at KERI signify hope for more environmentally-friendly and economically viable battery systems in the future.