The landscape of manufacturing is undergoing a seismic shift, and driving this change are humanoid robots like Boston Dynamics’ Atlas. Set to take its first steps into the industrial sector later this year at a Hyundai factory, Atlas represents a significant leap from its hydraulic predecessors. While this advanced robot has gained fame through entertaining viral video demonstrations, its entry into commercial manufacturing signifies a pivotal moment for automation and labor dynamics.

Unlike traditional factory settings that revolve around fixed, purpose-built automation processes, Atlas and its contemporaries symbolize a paradigm shift toward multipurpose functionality. The potential of these humanoid robots extends beyond mere efficiency; they offer an intriguing glimpse into how the integration of robotics could redefine the workplace as we know it.

The Strength to Transform

Atlas is touted not just for its cutting-edge engineering but also for its designed capabilities to outperform human workers in various tasks. According to Kerri Neelon, a spokesperson from Boston Dynamics, Atlas is engineered to handle weights and logistical challenges that humans might find cumbersome. This ability to perform physically demanding tasks positions Atlas not only as a tool but as an invaluable partner in labor-intensive environments, capable of working alongside human workers rather than replacing them outright.

This complex relationship between humans and robots raises questions about the future of labor and the potential for robots to enhance productivity. While critics caution against over-reliance on automation, the reality is that robots like Atlas can fill vital roles in industries where human labor may be impractical or hazardous. This evolution of robotics presents businesses with an opportunity to improve operational efficiency and worker safety, ultimately reshaping the labor environment.

Broader Implications for the Future

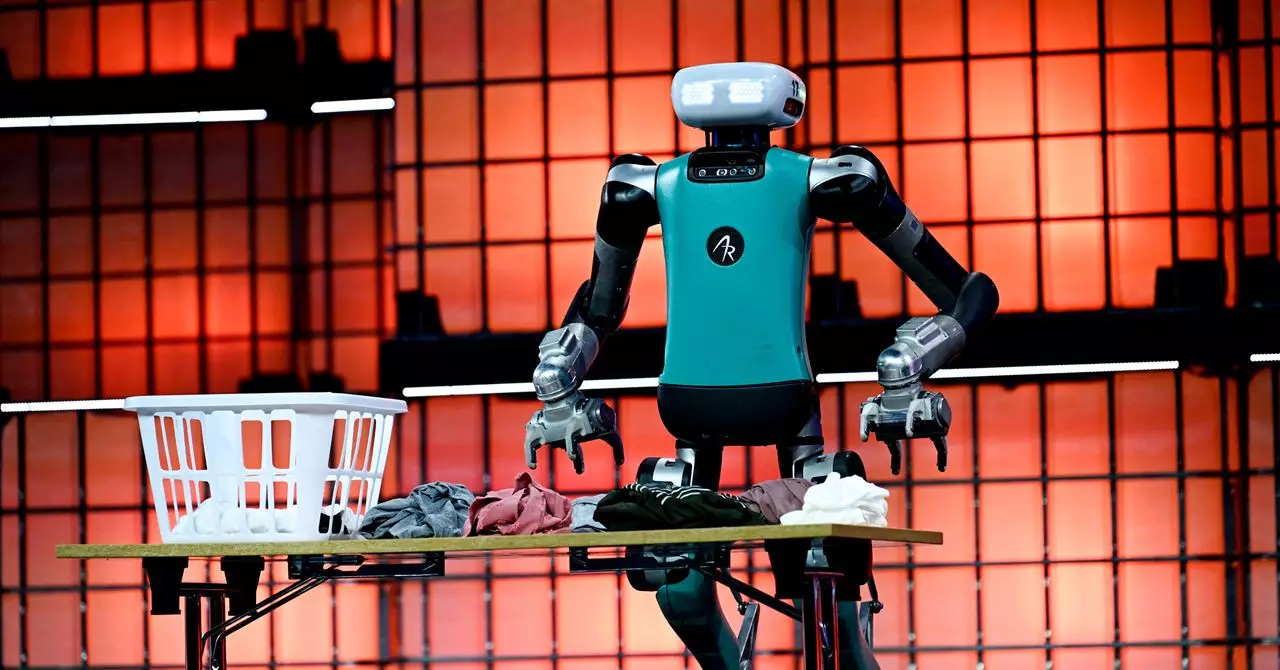

As humanoid robots like Atlas prepare to enter commercial settings, they are not alone. The market is anticipated to grow exponentially, with estimates indicating a $38 billion industry for humanoid robots by 2035, according to a Goldman Sachs report. Industry players such as Agility Robotics and even tech giants like Apple and Meta are exploring their own humanoid designs, signaling robust competition and innovation in this sector.

The advantages of versatility are significant; a flexible robot capable of adapting to varying tasks can yield greater productivity than specialized automation solutions that focus solely on one function. Jonathan Hurst, co-founder of Agility Robotics, emphasizes this point, noting that traditional automation works best for high-volume scenarios, while humanoid robots offer distinct advantages in environments characterized by varied and sporadic tasks.

This adaptability hints at a future where humanoid robots become integral components of manufacturing systems, seamlessly transitioning between roles typically suited to human workers. The implications are profound, suggesting a workforce that may increasingly find itself working harmoniously with machines.

Challenges and Considerations

However, venturing into the world of humanoid robotics isn’t without its hurdles. The recent buzz surrounding Tesla’s Optimus robot underscores the unpredictability of this nascent field. Tesla’s demonstration, which revealed that its robots were largely human-controlled, raised eyebrows regarding the viability of autonomous operation. As the industry grapples with the realities of production and performance, concerns about the feasibility and cost-effectiveness of widespread robot integration persist.

Boston Dynamics and its competitors must also navigate the complex landscape of materials sourcing. With geopolitical tensions affecting access to crucial components, as seen in the impact of U.S.-China trade policies, the path to scaling production could become increasingly convoluted. The pressing need for rare-earth metals highlights the interconnectedness of technology and global economics, complicating the race to bring humanoid robots like Atlas to full operational status.

The Human-Centric Approach

Amid the rush to innovate, Boston Dynamics promotes a philosophy of “human-first” design in robotics. With factories already evolving into safe environments for integrating automation, the vision is to create robots that complement rather than replace human capabilities. As the landscape shifts under the weight of technological advancements, it is crucial that humanoid robots are developed with a mindful approach that respects and enhances human labor.

In this unfolding narrative, the emergence of humanoid robots heralds more than just a technological revolution; it invites a re-examination of the very essence of work. As we move toward an increasingly machine-filled future, striking a balance between advancement and human-centric values becomes essential. The challenge lies not only in the mechanics of building intelligent robots but also in fostering a workplace culture that embraces innovation while honoring the irreplaceable qualities of human labor.