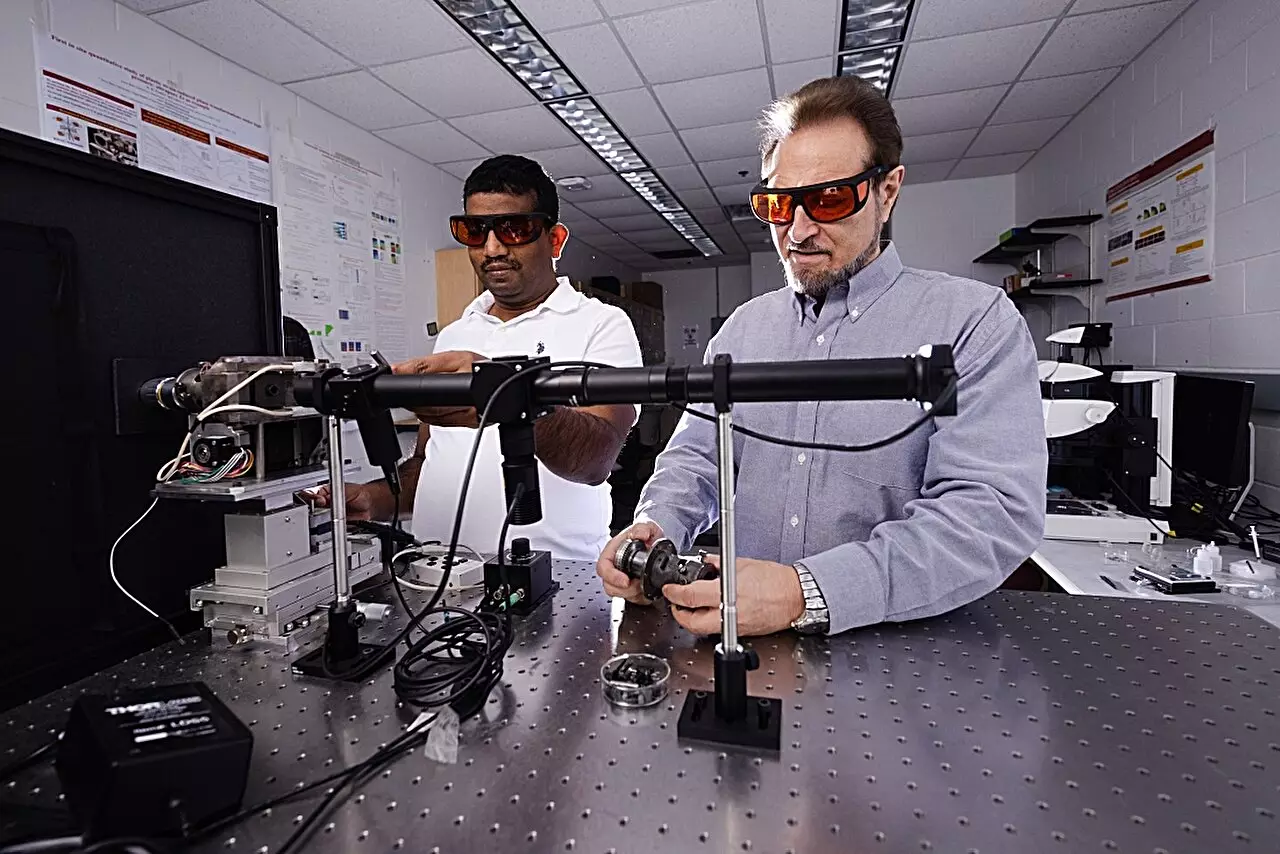

In 1999, Valery Levitas embarked on a groundbreaking journey as he transitioned from Europe to the United States, bringing with him a pioneering tool known as the rotational diamond anvil cell. This device has since evolved into a sophisticated apparatus for examining the intricate behavior of materials under extreme conditions. The research conducted by Levitas and his team at Iowa State University is at the forefront of understanding how pressure and shear forces interact to alter material properties. Through their work, they delve deep into the realms of material science, physics, and applied mechanics, moving beyond traditional boundaries to understand the nuanced changes materials undergo when subjected to stress.

One of the most significant findings from Levitas’s research focuses on silicon, a cornerstone in the electronics industry. Silicon is not merely a static element; rather, its structure is dynamic and can undergo unexpected transformations under conditions that are typically overlooked. The recent publication in Nature Communications highlights the team’s exploration of silicon exposed to high pressure coupled with plastic shear deformation. This innovative approach reveals that the conventional understanding of silicon’s phase transitions at high pressures is incomplete. Rather than following the linear path of transformation generally expected at around 16.2 gigapascals, silicon can exhibit radical phase changes at pressures as low as 0.3 gigapascals when subjected to unique strains.

Understanding Phase Transformations

The concept of phase transformations in materials is foundational to material science. When subjected to varying pressure and shear, silicon displays distinct behaviors tied to its crystalline structure. The findings shed light on how the material can transition from its “Si-I” phase to the “Si-II” phase with substantially reduced pressure requirements—literally enabling new pathways for innovation in material manipulation. Levitas emphasizes the shift in focus from merely changing a material’s macroscopic size or shape to enhancing its microstructural properties, which ultimately govern its functionality and applicability across industries.

The implications of these microstructural changes for practical applications are far-reaching. With advancements in technology and the increasing demand for novel materials, understanding how to manipulate silicon at uniform scales—such as nanostructured composites—becomes critical. By exploring silicon’s various phases, which are associated with distinct electronic and mechanical properties, researchers can potentially tailor materials for specific applications, offering significant enhancements over traditional silicon processes. As noted by Levitas, industries often face practical limitations when dealing with extremely high pressures. By employing the method of plastic deformation at more manageable pressures, new possibilities can emerge.

The potential for innovation in silicon research represents just the beginning. Levitas’s team is carving out a niche that not only utilizes traditional material science methods but also brings in advanced experimental techniques to unveil the unknown. Their exploration stands apart from conventional studies that rarely consider how the combination of pressure and deformation can create new phenomena. The long-awaited expectation for discovering these transformations was a driving force behind their experimentation; indeed, Levitas indicates that without anticipation of these low-pressure phase transformations, their research would not have progressed.

A Call to Action for Researchers

As Levitas and his colleagues continue to break the mold, they encourage the broader scientific community to engage in similar explorations. Understanding the potential and real-world applications of these transformations fuels the possibility for future engineering advancements. The interplay between theoretical predictions and practical experimentation lays the groundwork for new technologies that could revolutionize industries dependent on semiconductor materials. The horizon thus appears bright, brimming with opportunities for researchers willing to delve into the depths of material interactions and harness their findings in innovative ways.

The work of Valery Levitas and his team exemplifies the importance of interdisciplinary collaboration in unlocking the secrets of material behavior. By challenging existing paradigms and embracing experimental rigor, they not only enhance our understanding of silicon but also pave the way for future breakthroughs in material science.