Rare-earth elements (REEs) such as neodymium and dysprosium are vital components in the production of high-performance magnets, which find extensive applications in cutting-edge green technologies like electric vehicles and wind turbines. With the global shift towards renewable energy and electric mobility, the demand for these crucial materials continues to surge. As this demand escalates, the necessity for innovative recycling techniques becomes ever more pressing, particularly for end-of-life magnets that are increasingly prevalent in modern technology.

Recently, a team of researchers from Kyoto University, led by Professor Toshiyuki Nohira, developed a groundbreaking method known as the selective extraction–evaporation–electrolysis (SEEE) process. This innovative approach aims to enhance the recycling of REEs from obsolete magnets, moving towards a more sustainable and efficient mining and recycling methodology. Traditional recycling techniques are often plagued by their complexity and environmental repercussions. In contrast, the SEEE process stands out as a pioneering effort that could streamline the recovery of REEs with minimal ecological impact, thus supporting global carbon neutrality goals.

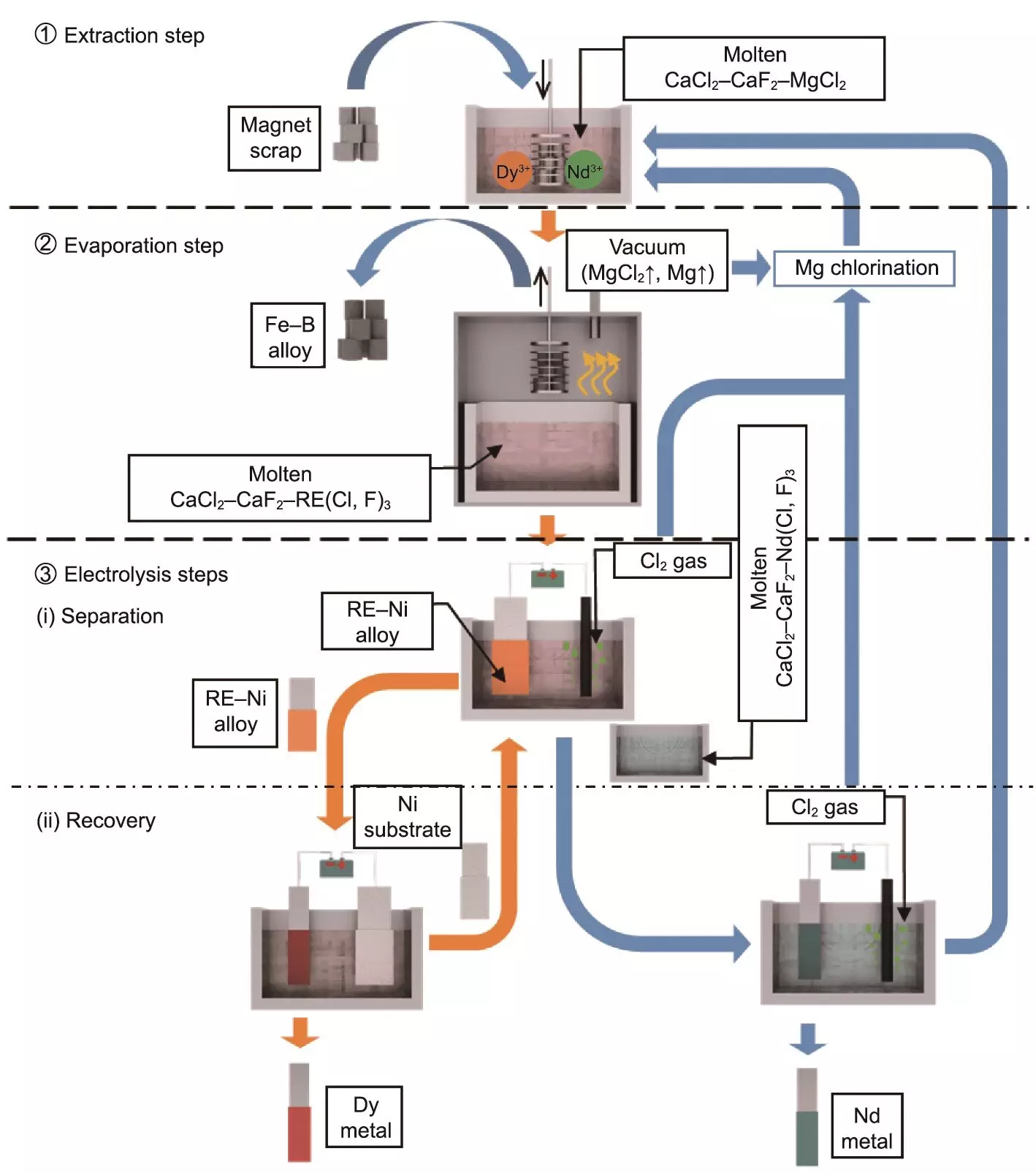

The SEEE process comprises three distinct stages, each designed to maximize the efficiency of REE extraction and purification:

1. **Selective Extraction**: In this initial phase, a molten salt mixture containing calcium chloride (CaCl2) and magnesium chloride (MgCl2) is utilized to draw out REEs from the magnet scraps. The incorporation of calcium fluoride (CaF2) plays a crucial role in minimizing evaporation losses, ensuring that the extraction of valuable materials is as efficient as possible.

2. **Selective Evaporation**: Following extraction, the process involves the removal of leftover extraction agents and byproducts through a controlled evaporation process. This step serves to concentrate the remaining REEs, optimizing the recovery yield.

3. **Selective Electrolysis**: The final stage of the SEEE process employs electrochemical separation based on the varying formation potentials of the extracted REEs. This technique allows for the isolation of high-purity neodymium and dysprosium metals, ensuring the quality needed for high-performance applications.

The remarkable efficiency of the SEEE process yields recovery rates of 96% for neodymium and 91% for dysprosium, with both elements achieving purities exceeding 90%. This significant advancement positions the SEEE process as a superior alternative to existing recycling methods.

The introduction of the SEEE process holds extensive implications for both the renewable energy sector and environmental sustainability efforts. As industries increasingly pivot towards electric vehicles and sustainable technologies, reliable recycling processes become essential to mitigate resource scarcity. By providing an efficient method for recovering REEs, the SEEE process reduces dependence on extraction from mines, which are often associated with substantial environmental degradation.

Moreover, the potential applications of the SEEE process extend beyond rare-earth magnet recycling. The researchers posit that this methodology could be adapted for other sectors, such as the reprocessing of nuclear fuels, thereby broadening its impact significantly. The adaptability of the SEEE technique not only contributes to the circular economy but also advances the scientific understanding of material recovery.

While the SEEE process demonstrates considerable promise in addressing the challenges associated with REE recycling, the researchers acknowledge that further technical investigations are necessary to transition this process into large-scale industrial applications. The initial findings from Kyoto University mark a significant milestone in material recycling research, highlighting the importance of developing breakthroughs that align with global environmental objectives.

As the world progresses toward a more sustainable future, innovations such as the SEEE process are critical in overcoming the obstacles inherent in rare-earth recycling. The necessity for effective and efficient recycling methods will only grow in the coming years, making the advancement of technologies like SEEE vital in supporting the transition to carbon-neutral and environmentally responsible practices.